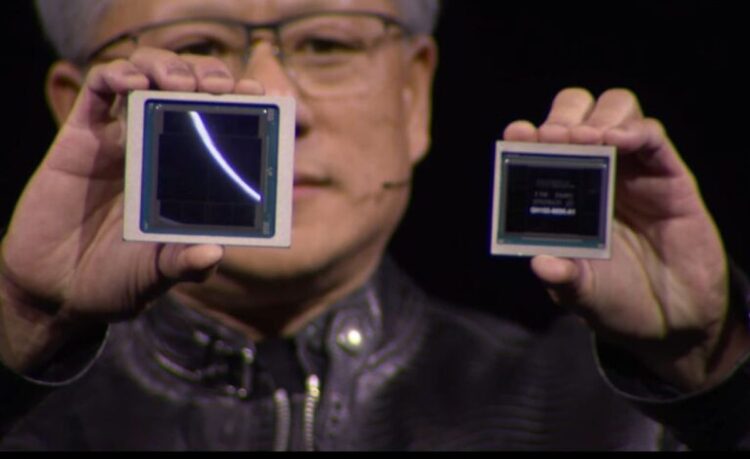

A few days ago, NVIDIA and TSMC announced that both companies had produced the very first US-made Blackwell GPU wafer at TSMC’s Fab 21 plant, in the state of Arizona. But as proud as the GPU brand is, producing the chip on US soil is just one part of the story: the wafer will still need to be shipped out to TSMC’s Taiwan plants to be packaged.

The packaging process we’re talking about is the Chip on Wafer on Substrate (CoWoS) packaging system, and the only facility capable of doing this is at TSMC’s factory in Taiwan – it’s the one place where the Taiwanese fab houses the technology for CoWoS-S configuration with silicon interposer. In this case, it’s where the next step of manufacturing for NVIDIA’s 4nm-class Blackwell nodes is further treated. In the case of its most recent die, the manufacturing process will it paired with eight stacks of HBM3E memory.

To be clear, this doesn’t mean that full chip production in the US isn’t going to happen for TSMC. According to TPU, the company is planning on outsourcing its packaging to Amkor, a packaging plant that is already setting up a plant in Arizona as well, while volume packaging is expected to start sometime in 2028. It’s no secret that the semiconductor supply chain is long and convoluted. Ex-AMD staff, James Prior, recalled just how many countries AMD’s Summit Ridge, otherwise known as the first generation Ryzen architecture – had to travel through, before ultimately ending up in hands of customers.

And to say nothing of the other issues that typically only show up down the line, making the aforementioned issues just the tip of the iceberg.

(Source: Videocardz)