Rimac, best known for its supercars, has unveiled advanced technologies at the IAA Mobility that could transform the electric vehicle (EV) industry as we know it. Among its innovations is the solid-state battery platform, designed to power an entirely new generation of mainstream electric cars.

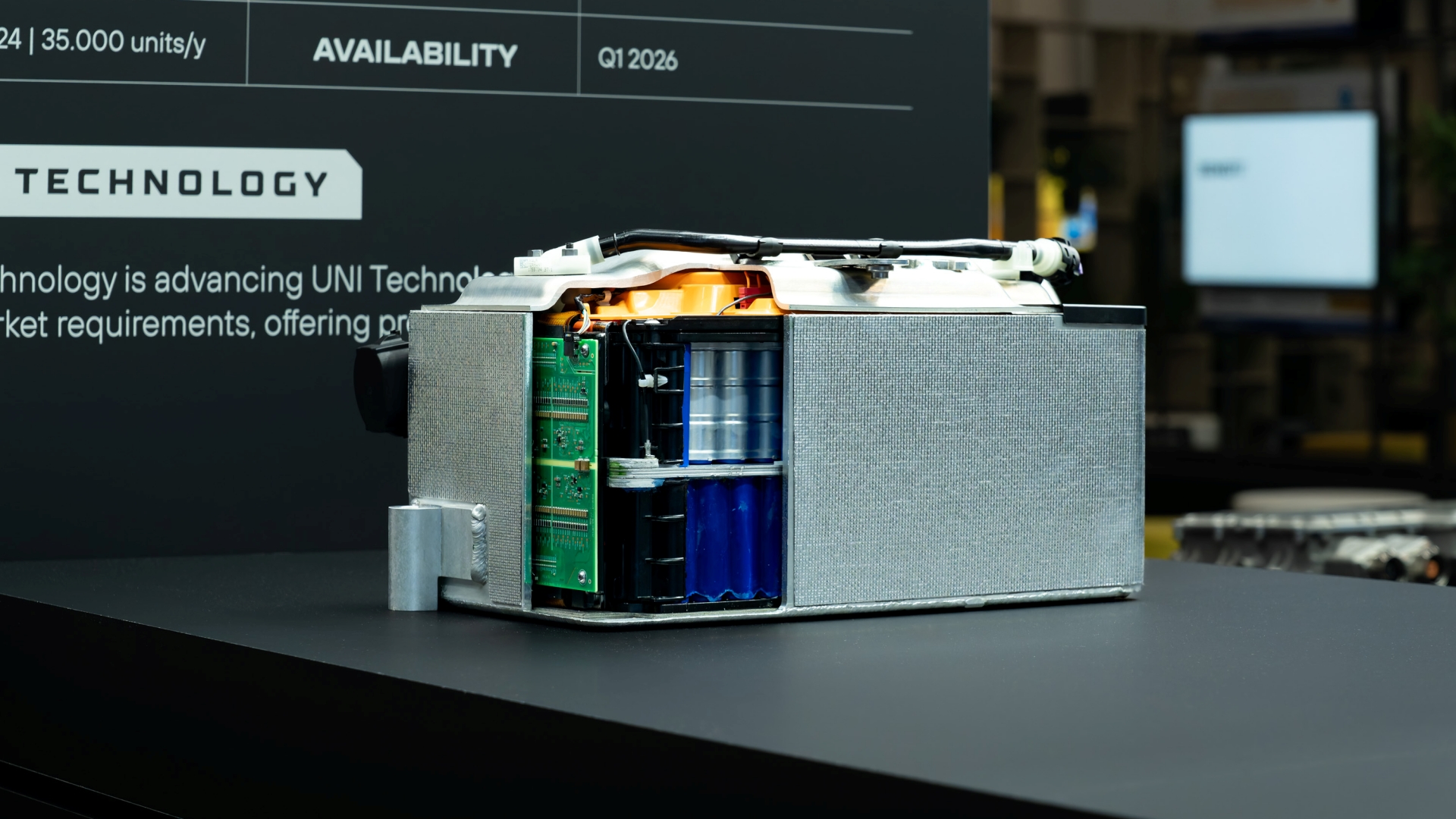

Solid-state batteries are widely regarded as the next big breakthrough in the EV sector, with many companies working on their development. However, Rimac has taken things a step further by creating a battery package that is lighter, safer, and more energy-dense. This innovation was developed in collaboration with ProLogium and the Mitsubishi Chemical Group. However, the exact specifications of the battery have yet to be unveiled by the company.

Rimac also introduced the “Evo” line technology, which represents a thermoplastic composite battery housing (Pentatonic) that is based on the 46XX cylindrical cells – a battery cell that is used by many EV companies. This technology line is co-developed with Kautex Textron and is designed as a more conventional battery solution for today’s market.

Furthermore, building on the same 46XX cylindrical cells, Rimac has developed a Hybrid line featuring a modular cell-to-pack design. It can be scaled to different sizes and supports interchangeable cell configurations. Moreover, it integrates advanced safety and thermal management features, making it adaptable for both high-energy and high-power applications.

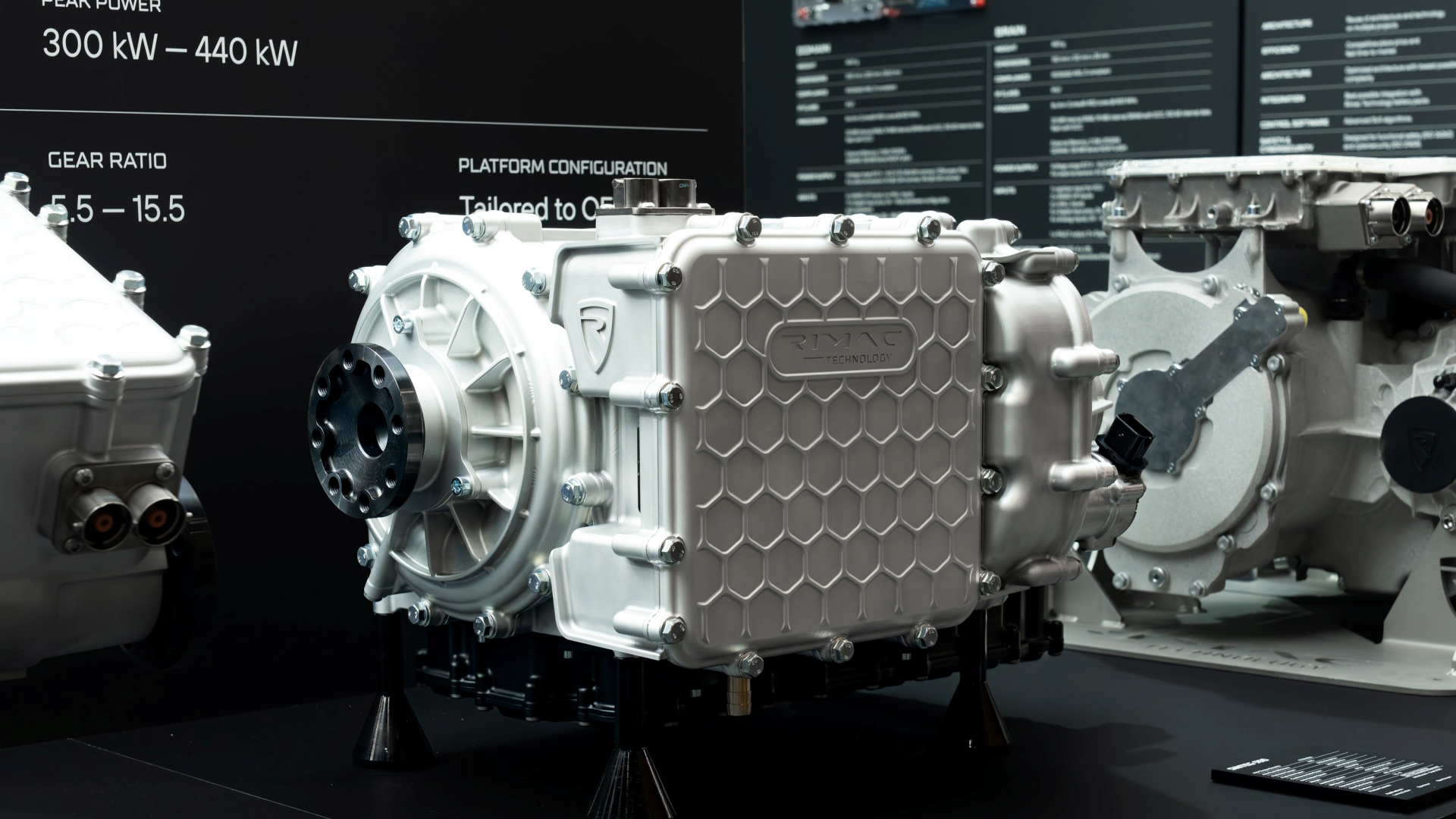

Another highlight of the technology line-up from Rimac is their new Sinteg 300 and 550 powertrains. The Sinteg 300 is a Single EM ultra-compact, fully integrated eAxle that combines motor, transmission and inverter in one drive unit. It has a small lightweight rotor that spins up to 25,000 rpm and delivers a power and torque density of 8 kW and 90 Nm per kilogram, respectively.

It has a power output between 150 kW to 360 kW and a torque that ranges between 2,500 Nm to 6,250 Nm. This means the powertrains can be used across all segments of vehicles, from hot hatches to performance-focused cars.

As for the Sinteg 550, it is a dual-motor “XXL axle” drive unit capable of delivering more than 11,000 Nm of torque at the axle while maintaining a peak efficiency of over 95%. This system is scheduled to enter production in 2026 for a major global automaker at its facility in Croatia, where all the other innovations will be produced as well.

Rimac already has a client list with names such as Porsche and BMW Group. Now, with these innovations, it seems the client list could grow further, and Rimac could take an important seat in the automotive industry, especially in the EV sector.

(Source: Rimac Press Release)