Xiaomi brought us to Beijing, China, for its big Human x Car x Home launch event, where it debuted a wide range of new gadgets and smart appliances. In the days leading up to the launch, we were treated to guided tours of its headquarters, as well as the Xiaomi EV Factory, where the company manufactures its SU7 models.

Upon arriving at the lobby, we were greeted by the sight of an SU7 Max suspended from the ceiling. The car is mounted on what the company calls a Mobius Strip frame, creating an eye-catching display drawing the immediate attention of every visitor.

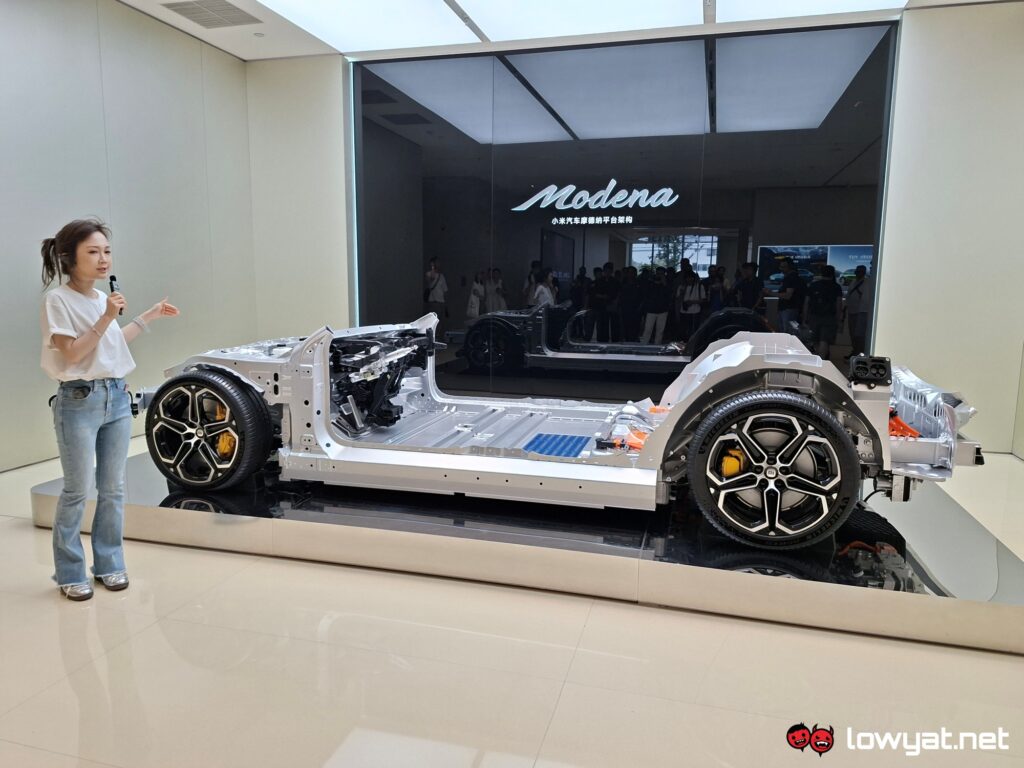

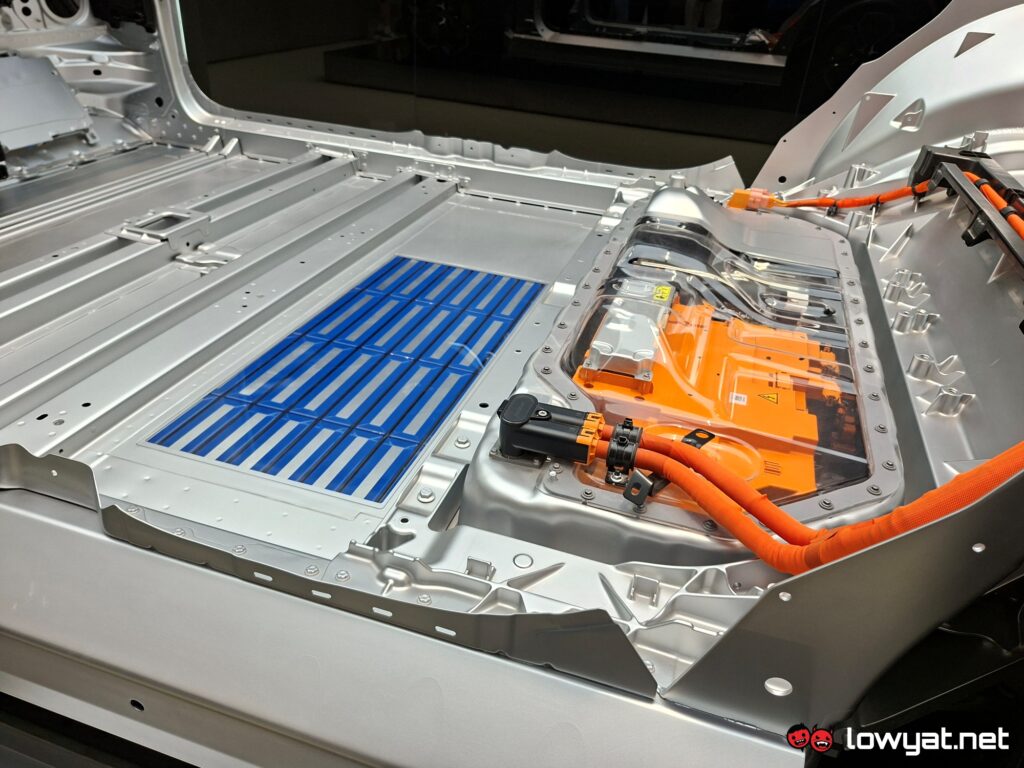

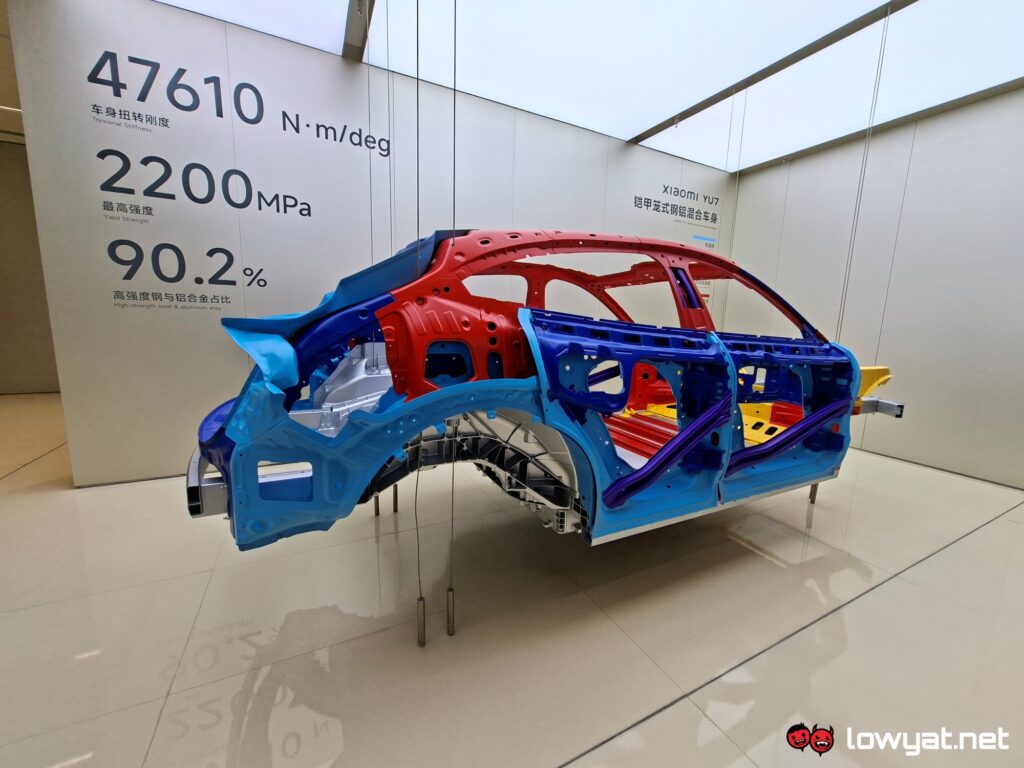

The first part of the tour brings us to the Experience Center, which houses the Technology Showroom. Here, we were given the rundown on the development of the brand’s EV models. The tour guide gave a quick rundown on some of the features of the Modena platform, which is the foundation for the brand’s vehicles. Also on display are the different engines used in the cars, as well as a colour-coded model of the YU7’s body structure highlighting the materials used.

The Experience Center also features an area showcasing the brand’s selection of EVs, including the different variants of the SU7 in a variety of colours. While not all design combinations can be seen in this room, there is a display of all the possible colours and finishes.

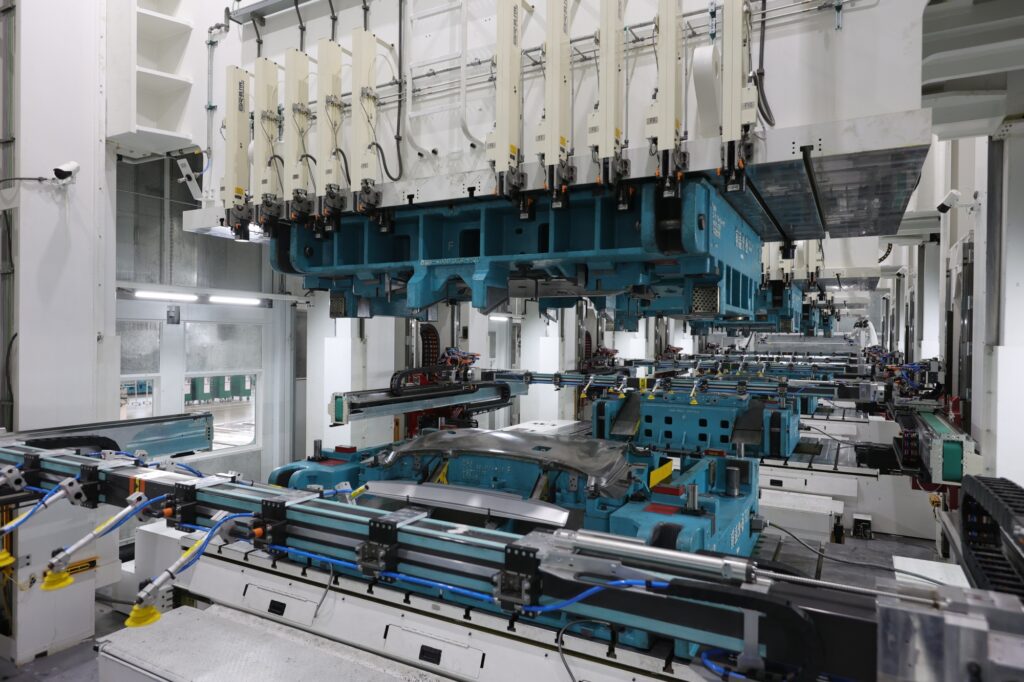

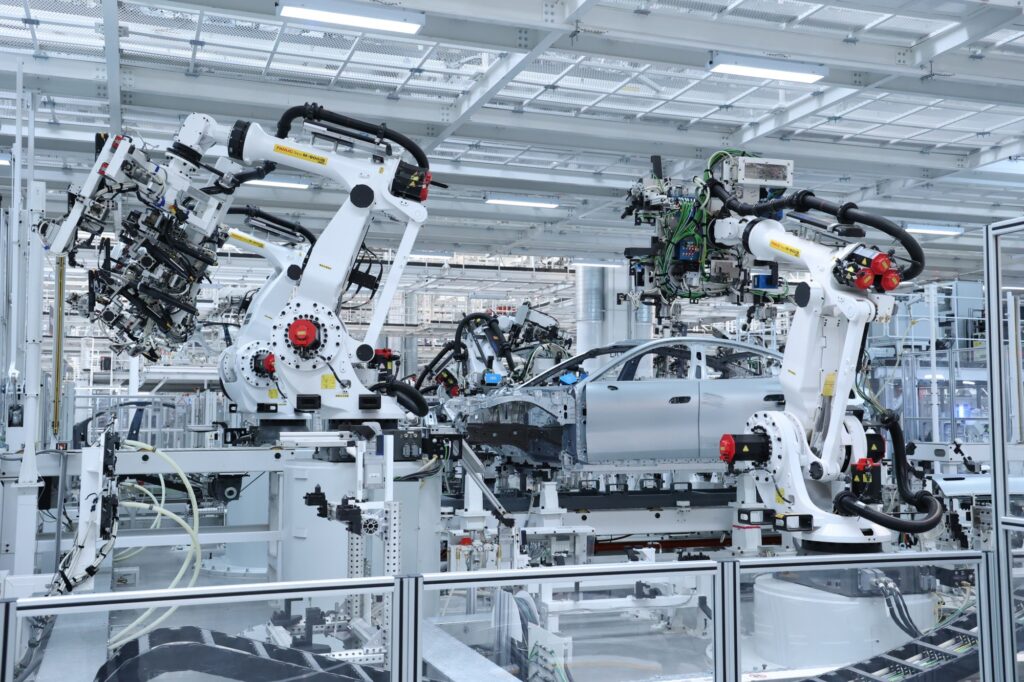

Then, we were taken to the Workshop, which houses the assembly line for the company’s EVs. Here, we were shown the major manufacturing processes of the SU7, which include die-casting, stamping, bodywork, painting, battery, and assembly. Unfortunately, Xiaomi has explicitly forbidden all filming and photography in this area, instead providing some of its own images depicting the individual parts of the workshop.

According to Xiaomi, the key processes are 100% automated using more than 700 robots, with very little human involvement. Each section is dominated by rows upon rows of robot arms manoeuvring the car components into place. As to how the parts are moved across the production line, it’s thanks to the AMR vision robots that can be seen milling about the factory. These robots can coordinate with each other and adjust their paths depending on the conditions in the workshop.

Xiaomi claims that the factory is capable of assembling a car in just 76 seconds, and with production capacity fully ramped up, 40 SU7s are manufactured every hour. The company also notes that there is a brief gap between each car produced, which explains the discrepancy between the figures provided.

We finished the tour at the Testing Track, which is where the vehicles are taken for a spin to determine whether they meet the company’s standards. Part of the tour involves a very brief ride on the SU7 Max, just to get a small taste of the car’s capabilities.

And so concludes the visit to Xiaomi’s first EV factory. It is worth noting that the company does offer guided tours of the facilities, including the workshop areas. However, tickets for the tour can only be acquired through the Xiaomi EV app.

And so concludes the visit to Xiaomi’s first EV factory. It is worth noting that the company does offer guided tours of the facilities, including the workshop areas. However, tickets for the tour can only be acquired through the Xiaomi EV app.