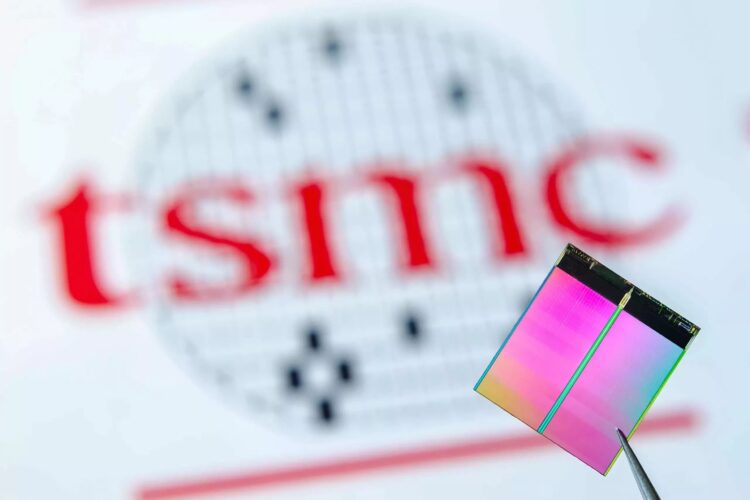

TSMC recently unveiled its next generation manufacturing process, A14. The Taiwanese fab made the announcement last week in the US and is set to enter mass production in 2028.

The A14 process is basically another name for the 1.4nm process, meaning that the “A” in the name may refer to the Angstrom unit of measurement. according to the company, A14 will offer up to 15% increase in speed over N2, up to 30% reduction in power consumpti

Another key feature of the A14 is NanoFlex Pro, which is an evolution of the NanoFlex standard cell architecture.

TSMC continues to advance its Chip on Wafer on Substrate (CoWoS) technology to address AI’s insatiable need for more logic and high-bandwidth memory (HBM). The company plans to bring 9.5 reticle size CoWoS to volume production in 2027, enabling integration of 12 HBM stacks or more in a package together with TSMC’s leading-edge logic technology. After showcasing its revolutionary System-on-Wafer (TSMC-SoW) technology in 2024, TSMC followed up with SoW-X, a CoWoS-based offering to create a wafer-sized system with computing power 40X the current CoWoS solution. Volume production is scheduled for 2027.

As the A14 process isn’t expected to enter mass production until 2028, the fab is also planning on releasing an A16 process next year, to serve as a buffer between now and then. In the meantime, TSMC is expected to reach volume production for its N3X process, the successor to its current N3P process, which went into mass production back in the fourth quarter of 2024.