Sony’s R&D team has created a unique set of curved CMOS image sensors that promises to revolutionize the digital imaging industry. Using a “bending machine” that is developed in-house, Sony’s curved CMOS sensors mimics the curvature of the human eye.

According to Sony’s engineers, the curved sensors have a curvature that is similar to the human eye. As a result, these sensors offer 1.4 times more sensitivity in the middle, and 2 times better sensitivity in the corners. In comparison to the usual planar sensors, the new curved sensors have plenty of added benefits, according to Kazuichiro Itonaga, a device manager with Sony’s R&D Platform.

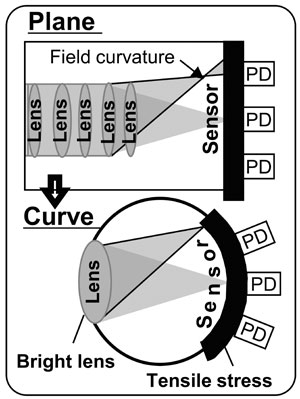

Because of the geometry, it can be paired with a flatter lens and a larger aperture, which lets in more light. Photodiodes at the periphery of a sensor array will be bent toward the center, which means light rays will hit them straight on instead of obliquely. What’s more, the strain induced on a CMOS sensor by bending it alters the band gap of the silicon devices in the sensor region, lowering the noise created by “dark current” — the current that flows through a pixel even when it is receiving no external light.

This isn’t the first curved CMOS sensor that’s been developed -there was one concept from 2008 that never quite took off – but what separates Sony’s new sensors is in the company’s ability to mass-manufacture the sensors. Itonaga states that it has already produced close to 100 full-sized sensors using the bending machine. In addition to the full-frame 43mm sensor, Sony has also developed a smaller curved sensor that can be fitted into mobile devices. This sensor measures 11mm at the diagonal, and features smaller pixels.